Project Overview

Class 3 PCB fabrication depends on real tolerances that never appear on a drawing or inside a CAD tool. This project explains the five tolerance behaviors that most often determine whether a high reliability board builds cleanly or struggles in production.

What This Project Covers

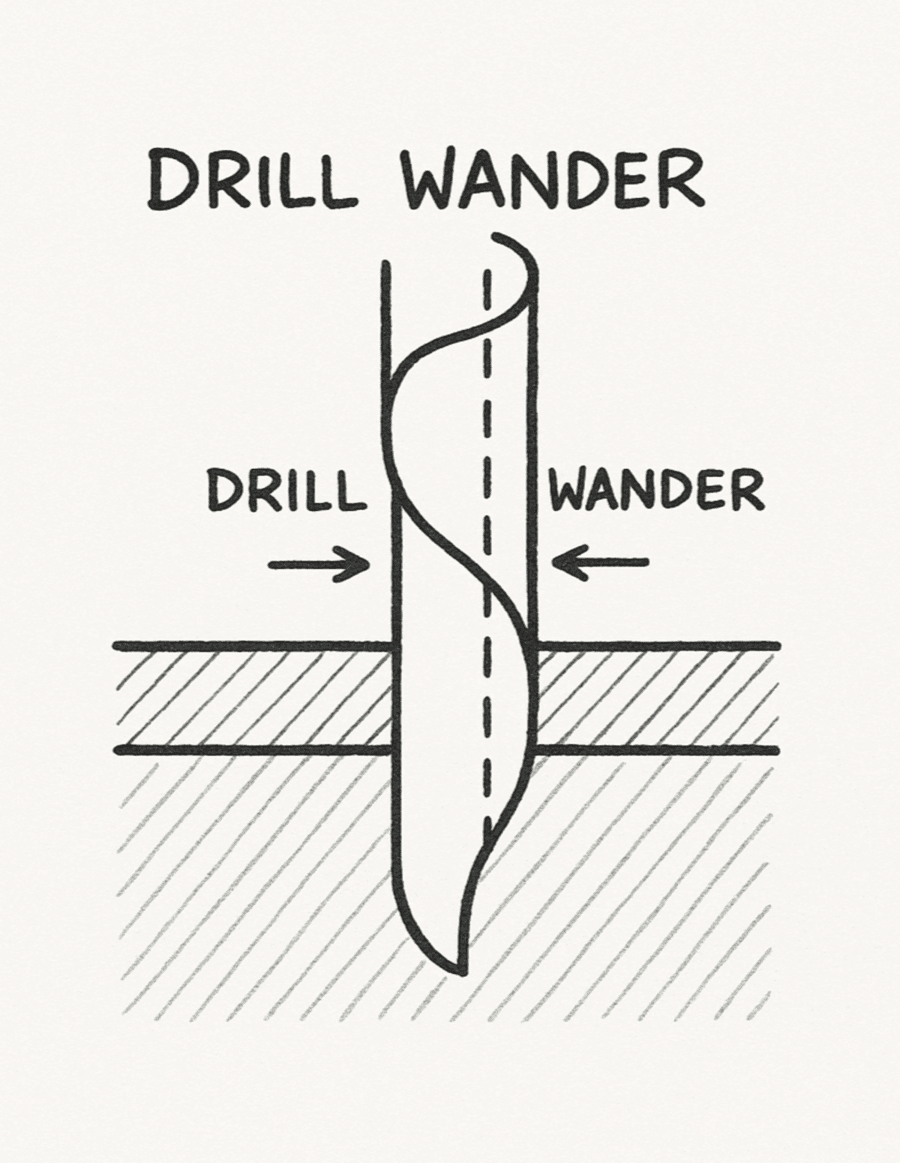

- How drill wander affects annular ring margins

- Why plating growth changes finished hole sizes

- How lamination cycles shift registration in predictable directions

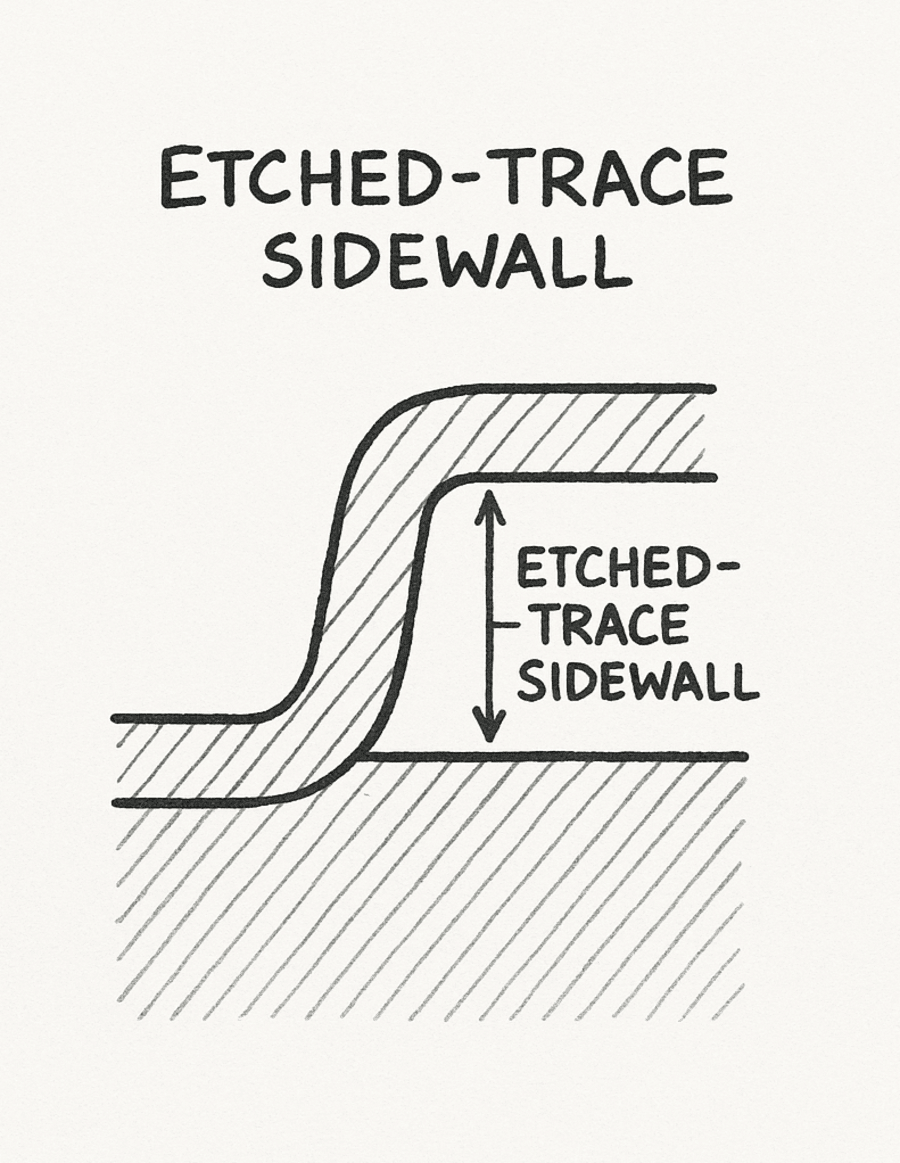

- Why copper etching creates tapered sidewalls

- How real materials differ from datasheet values

These observations come from the fabrication side, from what actually happens on the panel, inside the press, and under the microscope, so designers can understand the real limits behind Class 3 builds.

Ryan O'Connor

Ryan O'Connor

colton.baldridge

colton.baldridge

Victor Dedios

Victor Dedios

Thanks to everyone checking this out. If there are tolerance-related issues you’ve seen in your own Class 3 builds, feel free to leave them. I’m collecting real cases for a follow-up log.