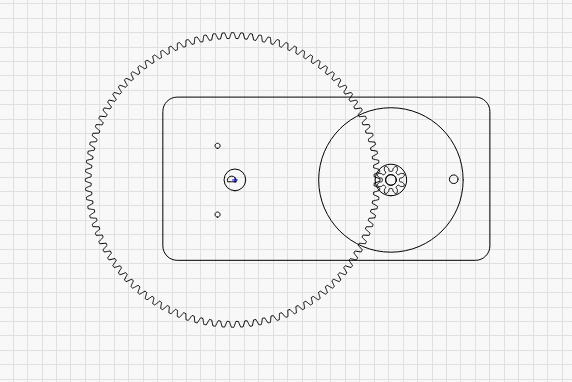

The 4.8 RPM motor is likely salvaged from clock. I leveraged Generative AI to shortcut finding the gear ratio and tooth counts for the gears involved. I was shocked at how well this worked. I then tested the result in an online gear simulator to verify the results were indeed 60 RPM. Gemini suggested multiple options including some 2 stage intermediate gears. It noted that only using 2 gears would be possible but the drive gear would be pretty large and the driven gear very small which might not be optimal. I opted for the simple 2 gear route since the gear wasn't that big and it would fit in my laser cutter. The drive gear has 100 teeth and the driven gear has 8 giving me the precise 12.5 gear ratio needed to move a hole in a disk of wood at 60 RPM over an always on LED to simulate it blinking at 1 hz.

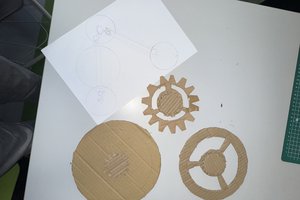

Everything is cut from 4mm plywood on a diode laser. This was faster than 3D printing the parts. If the intention was for it to be compact and portable then 3D printing would make much more sense.

To create the gears I used this handy gear generator utility: https://evolventdesign.com/pages/spur-gear-generator This allowed me to save the gear designs as .SVGs and import them directly into LightBurn for fine tuning and cutting. This same SVG could be modified in CAD to a 3D part for printing.

I used a bearing I had laying around that just happened to snugly fit onto a dowel that I also just happened to have laying around. Everything is pretty much friction fit together. I did add some superglue just in case.

Everything is mounted on a common board. I did end up having to slot the mounting holes for the motor to fine tune the gear engagement.

LED is just jammed in an undersized hole.

I learned a ton about gears during this "project to nowhere" and also yet another use for Generative AI.

These learnings will help me with the clock project as I shift back to that. I anticipate many intermediate gear shenanigans to get seconds, minutes and hours to display.

jeremy.geppert

jeremy.geppert

maxandre.lena

maxandre.lena

Arnov Sharma

Arnov Sharma

Keith Elliott

Keith Elliott